The relentless march towards an electrified automotive future hinges critically on one core component: the battery. While lithium-ion (Li-ion) batteries have been the workhorse of the first wave of electric vehicles (EVs), powering everything from compact city cars to high-performance sedans, their inherent limitations are becoming increasingly apparent as the industry strives for greater range, faster charging, enhanced safety, and reduced costs. The quest for the "next big thing" in battery technology is more fervent than ever, with researchers and companies worldwide racing to unlock new chemistries and designs that can propel the EV revolution into its next phase. This article delves into the exciting landscape of advanced battery technologies poised to go beyond lithium-ion, exploring their potential, challenges, and the transformative impact they could have on the automotive world, further accelerating the electric vehicle revolution.

The Reign and Limitations of Lithium-Ion Batteries

Lithium-ion technology has undeniably revolutionized portable electronics and has been instrumental in making EVs a viable alternative to internal combustion engine vehicles. Understanding its rise and current constraints is crucial to appreciating the drive for innovation.

Why Lithium-Ion Became Dominant

The widespread adoption of Li-ion batteries in EVs can be attributed to a confluence of favorable characteristics. They offer a relatively high energy density, meaning they can store a significant amount of energy in a given weight or volume, which is critical for achieving practical driving ranges. Furthermore, Li-ion batteries have demonstrated a good cycle life, capable of enduring hundreds to thousands of charge-discharge cycles before significant degradation. Over the past decade, concerted research and manufacturing scale-up have also led to a dramatic reduction in their cost, making EVs progressively more affordable. Their versatility has allowed for various form factors, including cylindrical, prismatic, and pouch cells, catering to diverse vehicle packaging requirements.

Unpacking the Challenges

Despite their successes, Li-ion batteries face several intrinsic and practical limitations that hinder the full potential of EVs. Energy density, while good, is approaching a theoretical plateau for conventional chemistries, making substantial range improvements increasingly difficult without adding more weight and cost. Safety remains a concern, with the flammable liquid electrolyte posing a risk of thermal runaway if cells are damaged or improperly managed, leading to fires. Charging times, although improving, are still significantly longer than refueling a gasoline car, which is a major barrier for some consumers. Moreover, the supply chain for key materials like lithium, cobalt, and nickel is geographically concentrated and faces geopolitical risks, price volatility, and ethical sourcing concerns, particularly for cobalt. While costs have fallen, batteries still represent the single most expensive component of an EV, and further reductions are needed for mass-market parity with combustion vehicles.

Contenders for the Throne: Emerging Battery Chemistries

The push for superior battery performance has ignited a global research and development race, with several promising chemistries emerging as potential successors or complements to lithium-ion. Each offers a unique set of advantages and faces its own developmental hurdles.

Solid-State Batteries: The Frontrunner?

Solid-state batteries (SSBs) are widely regarded as one of the most promising next-generation technologies. They replace the flammable liquid electrolyte found in conventional Li-ion batteries with a solid material, which can be ceramic, polymer, or a composite. This fundamental change promises several key benefits: significantly enhanced safety due to the non-flammable nature of the electrolyte, higher energy densities by enabling the use of lithium metal anodes, and potentially longer cycle life and faster charging capabilities. Many major automakers and battery manufacturers are heavily investing in SSB research, with some projecting initial commercialization in vehicles within the mid to late 2020s. However, significant challenges remain. Manufacturing SSBs at scale and at a competitive cost is a major hurdle. Ensuring high ionic conductivity through the solid electrolyte at various operating temperatures, maintaining good contact between electrodes and the electrolyte over many cycles (especially with volume changes during charge/discharge), and developing robust manufacturing processes are active areas of research. The promise is immense, but the path to widespread adoption is still being paved.

Lithium-Sulfur (Li-S) Batteries: High Theoretical Capacity

Lithium-sulfur batteries offer an enticingly high theoretical specific energy, potentially five times that of conventional Li-ion batteries. Sulfur is also abundant, inexpensive, and environmentally benign, making Li-S an attractive prospect from a cost and sustainability standpoint. In a Li-S cell, lithium ions react with sulfur during discharge. The primary challenges hindering Li-S commercialization include the "polysulfide shuttle" effect, where soluble lithium polysulfides migrate between electrodes, leading to capacity fade and low coulombic efficiency. Sulfur's insulating nature and the significant volumetric expansion/contraction during cycling also contribute to poor cycle life and structural instability. Researchers are exploring various strategies like novel cathode materials, electrolyte additives, and protective interlayers to mitigate these issues and unlock the vast potential of Li-S technology.

Lithium-Air (Li-O2) Batteries: The Ultimate Energy Density?

Lithium-air, or lithium-oxygen, batteries boast the highest theoretical energy density among known battery chemistries, comparable to that of gasoline. They work by reacting lithium with oxygen sourced directly from the ambient air, effectively making the cathode "weightless" as it doesn't need to carry its own oxygen source within the battery cell. This could theoretically lead to ultra-lightweight batteries capable of delivering driving ranges exceeding 1000 kilometers on a single charge. However, Li-O2 batteries are perhaps the furthest from commercial reality due to formidable scientific and engineering challenges. These include electrolyte degradation, the formation of passivating byproducts on the lithium anode, clogging of the air electrode, and very poor round-trip efficiency and cycle life. Overcoming these hurdles requires breakthroughs in materials science and electrochemistry.

Sodium-Ion (Na-ion) Batteries: The Cost-Effective Alternative

Sodium-ion batteries are gaining traction as a potentially cheaper and more sustainable alternative to lithium-ion, particularly for applications where ultra-high energy density is not the primary concern. Sodium is vastly more abundant than lithium and shares similar chemistry, allowing for the adaptation of existing Li-ion manufacturing infrastructure. Na-ion batteries also tend to perform better at very low temperatures and can be fully discharged to zero volts for safer transport and storage. While their energy density is generally lower than Li-ion, making them less suitable for long-range premium EVs, they are promising for smaller urban EVs, electric two-wheelers, and particularly for stationary energy storage. Recent advancements have improved their energy density and cycle life, with some companies already beginning commercial production. Their lower cost and more stable supply chain could make them a key player in democratizing electric mobility and energy storage.

Other Promising Avenues

Beyond these leading contenders, researchers are also exploring other chemistries. Magnesium-ion batteries offer the potential for higher volumetric energy density and improved safety due to magnesium's divalent nature and non-dendritic plating. Zinc-ion aqueous batteries are being investigated for their low cost, safety, and environmental friendliness, though energy density and cycle life are current limitations. Even flow batteries, traditionally used for grid-scale storage, are being explored in novel configurations for EV applications, though their complexity and lower energy density present challenges.

Innovations in Battery Design and Management

Beyond new chemistries, significant advancements are also occurring in how batteries are constructed, packaged, and managed. These innovations aim to extract maximum performance, safety, and longevity from both current and future battery technologies.

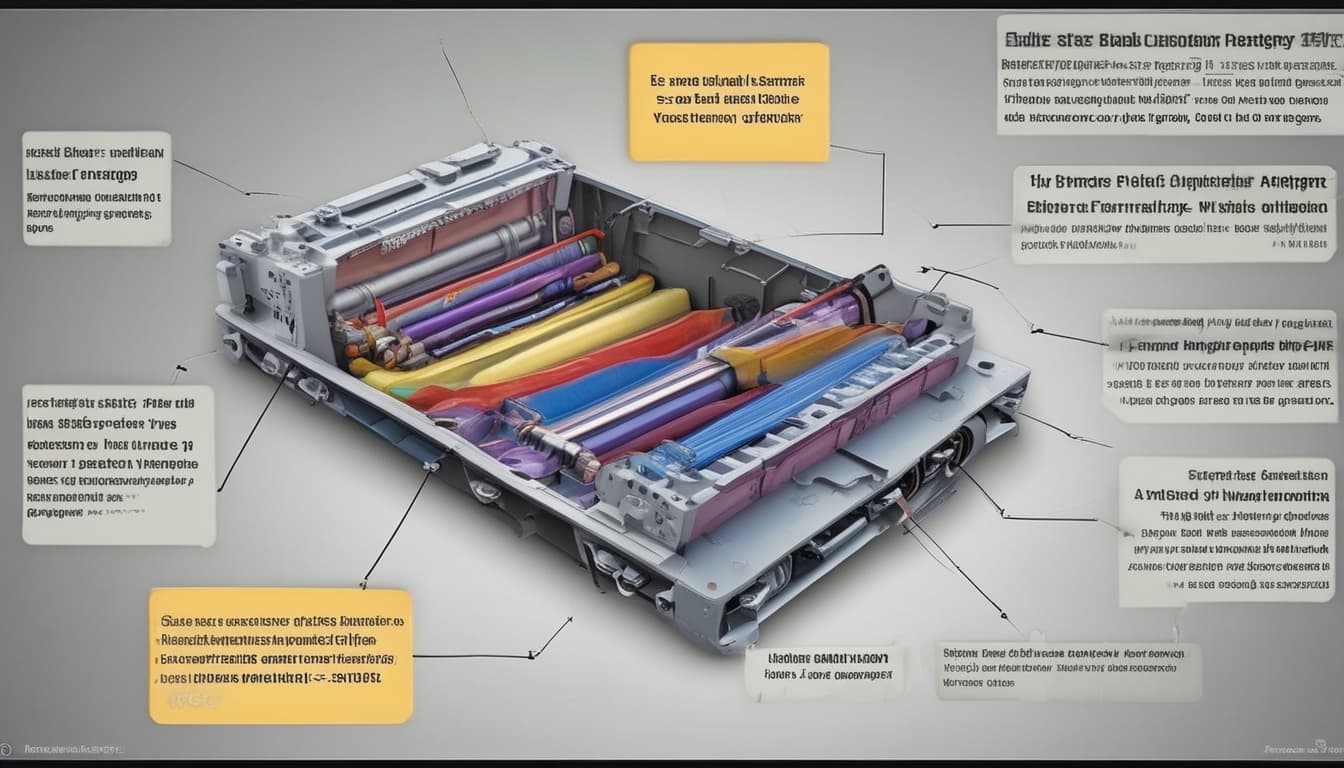

Advanced Cell and Pack Architectures

Battery pack design is evolving rapidly. Traditional packs consist of numerous small cells grouped into modules, which are then assembled into a pack. Newer approaches like cell-to-pack (CTP) and cell-to-chassis (CTC) eliminate the module level, directly integrating cells into the pack structure or even the vehicle's chassis. This improves volumetric and gravimetric energy density, simplifies manufacturing, reduces cost, and can enhance structural integrity. Improved thermal management systems are also crucial. Liquid cooling, advanced heat dissipation materials, and sophisticated control strategies are essential for maintaining cells within their optimal temperature range, preventing thermal runaway, and enabling faster charging.

AI and Machine Learning in Battery Management Systems (BMS)

The Battery Management System (BMS) is the brain of the battery pack, responsible for monitoring its state, ensuring safe operation, and optimizing performance. The integration of Artificial Intelligence (AI) and Machine Learning (ML) is revolutionizing BMS capabilities. AI algorithms can analyze vast amounts of data from sensors within the battery to provide far more accurate estimations of State of Charge (SoC), State of Health (SoH), and Remaining Useful Life (RUL). This enables more precise range predictions, optimized charging strategies to prolong battery life, and early detection of potential faults. Explore how AI is revolutionizing vehicle systems for a broader perspective on its impact. Furthermore, AI-driven BMS can adapt to individual driving patterns and environmental conditions, tailoring battery operation for maximum efficiency and longevity, aligning with advancements in predictive maintenance for enhanced vehicle reliability. The broader applications of generative AI are also transforming the automotive industry in various aspects beyond just battery management.

Wireless BMS and Enhanced Connectivity

Another significant trend is the development of wireless BMS (wBMS). By eliminating the extensive wiring harnesses typically required to connect individual cells and modules to the BMS controller, wBMS can reduce weight, complexity, and assembly costs. It also offers greater flexibility in pack design and can improve reliability by removing potential points of failure associated with physical connectors. Enhanced connectivity, often leveraging IoT principles, allows the BMS to communicate with cloud-based platforms. This enables remote diagnostics, over-the-air software updates for the BMS, and the aggregation of fleet-wide battery data for continuous improvement and algorithm refinement. This integration highlights the transformative synergy between electric vehicles and IoT technologies.

The Road Ahead: Overcoming Hurdles and Scaling Up

The journey from laboratory breakthrough to mass-market adoption for new battery technologies is fraught with challenges. Scaling up production, ensuring robust supply chains, reducing costs, and establishing industry standards are all critical steps.

Manufacturing and Supply Chain Challenges

Each new battery chemistry presents unique manufacturing challenges. Processes developed for Li-ion may not be directly transferable, requiring significant investment in new equipment and techniques. The adoption of 3D printing and advanced manufacturing techniques will be crucial for scaling up production efficiently. For instance, solid-state batteries might require novel deposition or sintering processes, while Li-S batteries need solutions for handling sulfur and managing its byproducts. Securing a stable and ethical supply of raw materials is paramount. While some new chemistries aim to reduce reliance on problematic materials like cobalt, they may introduce dependencies on other resources. Establishing resilient and geographically diverse supply chains will be crucial. The emphasis on adopting sustainable practices throughout the automotive supply chain is more critical than ever when considering new material sourcing for these advanced batteries.

Cost Reduction Strategies

For any new battery technology to succeed, it must ultimately achieve a cost point that makes EVs competitive with or cheaper than internal combustion vehicles without subsidies. This involves not only reducing the cost of raw materials and cell components but also optimizing manufacturing processes for economies of scale. Innovations in cell design, pack assembly, and recycling will all play a role in driving down the overall battery pack cost.

Standardization and Safety Regulations

As new battery technologies emerge, industry-wide standards for performance, safety, and testing will need to be developed and adopted. This ensures interoperability, facilitates easier integration by automakers, and builds consumer confidence. Rigorous safety testing and certification protocols are essential to mitigate any new risks associated with novel materials or designs, ensuring that these advanced batteries are as safe as, or safer than, current technologies.

The Role of Recycling and Second-Life Applications

Creating a circular economy for EV batteries is vital for long-term sustainability and resource management. Developing efficient and cost-effective recycling processes for new battery chemistries will be essential to recover valuable materials and reduce reliance on primary mining. Furthermore, batteries that no longer meet the demanding requirements of automotive use can often find a "second life" in less strenuous applications, such as stationary energy storage for homes or the grid. This approach not only extends the battery's useful life but also maximizes its economic value, contributing to a more sustainable automotive ecosystem through circular economy principles.

Conclusion: Powering the Future of Mobility

The pursuit of advanced battery technologies beyond lithium-ion is a critical enabler for the next generation of electric vehicles. From the promising safety and energy density of solid-state batteries to the potential cost advantages of sodium-ion and the ultra-high theoretical capacity of lithium-sulfur and lithium-air, the landscape is vibrant with innovation. While significant challenges in manufacturing, cost, and material science remain, the concerted efforts of researchers, startups, and established industry players are steadily pushing the boundaries of what's possible.

Innovations in battery design, such as cell-to-pack architectures, and intelligent management systems powered by AI, are further amplifying the potential of these new chemistries. The road ahead requires continued investment, collaboration, and a holistic approach that encompasses not just cell chemistry but also pack engineering, supply chain sustainability, and end-of-life management.

The successful development and deployment of these next-generation batteries will unlock EVs with longer ranges, faster charging times, enhanced safety, and lower costs, accelerating the global transition to sustainable transportation. The journey is complex, but the destination—a cleaner, more efficient, and electrified automotive future—is well worth the endeavor.

We invite you to join the conversation on Fagaf. Share your insights, ask questions, and discuss the future of automotive battery technology with fellow enthusiasts and experts. What battery advancements are you most excited about?